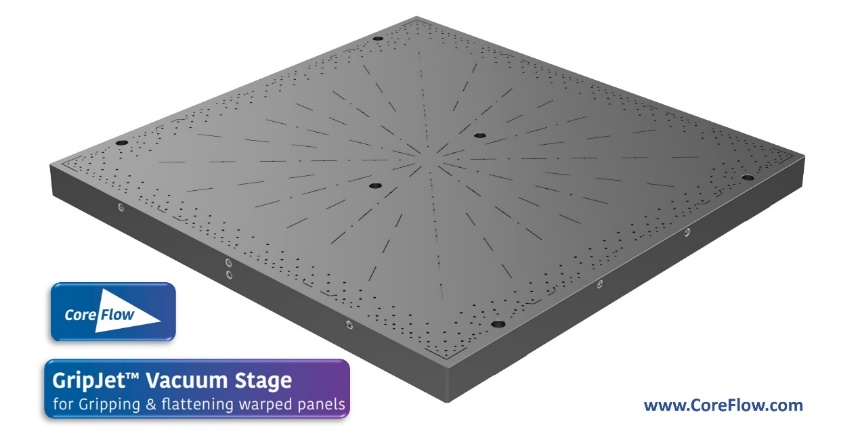

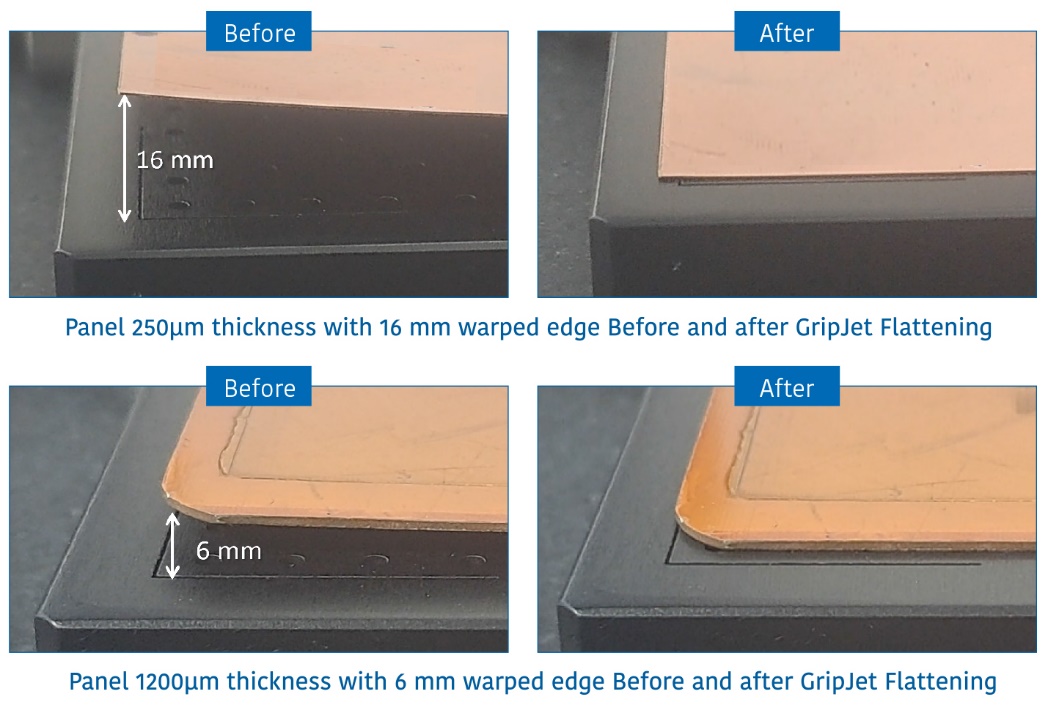

Warped Panels Flattening with GripJet™ Stage

- GripJet Vacuum stage with patented mass flow rate amplifier

- No Elastomers or soft pads

- Build to print:Customization per user

- Standard vacuum and pressure suppliers

- No moving parts

- No consumables

- Applications: Panel-Level Package (PLP), PCB, Glass carriers, and others.

- Processes: AOI, Metrology, Defect Inspection, Lithography, and other process in an atmospheric environment.

- Substrates: FR4, Glass, Copper-clad substrate, Organic substrates, and others

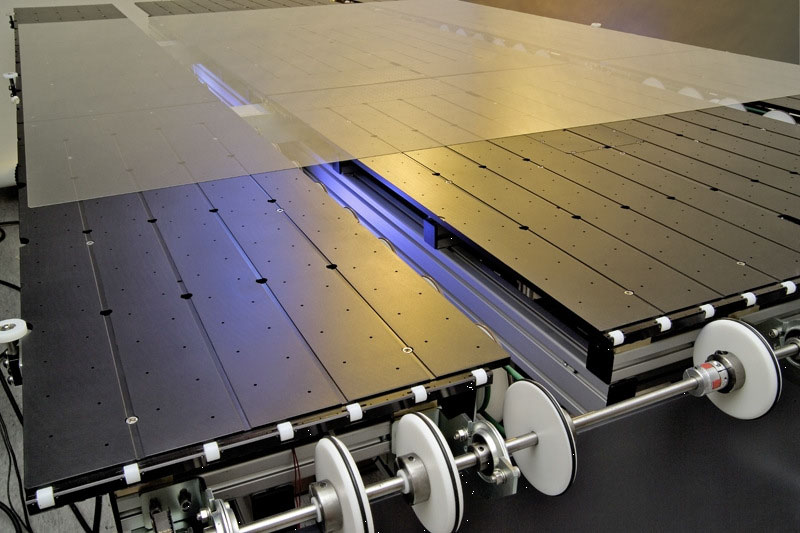

CoreFlow pressure atmospheric (PA) and pressure vacuum (PV) stages enable precise, non-contact handling that reduces backside particle contamination.

- Solution provider

- Flexibility

- Build to print:Customization per user

- High Precision

- Enhance Throughput

- Increased Yield

- OLED & QD inkjet printing

- AOI

- Slit coating

- Laser scribing

- UV Curing

- Factory

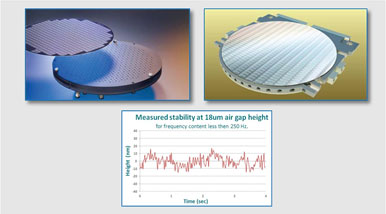

Driven by the high requirements of wafer handling, CoreFlow addresses the challenges of reducing back side contamination and handling thin and flexible wafers, for various applications within the semiconductor process

- Increases process yield

- Eliminates back side contamination

- Attenuates vibrations

- Levels warped wafers

- Reduces thermal stresses

- Enables flexible design

- AOI

- Metrology…e.t.c.

CoreFlow’s selective vacuum solution addresses the challenges of handling warped wafers. Utilizing its SmartNozzleR technology, CoreFlow’s handling mechanism acquires the wafer even when only a fraction of the vacuum array is covered. This is in contrast to competing technologies, where a standard vacuum chuck would lose its gripping force and drop the wafer.

- Eliminates vacuum loss caused by high flow via uncovered vacuum holes.

- Low risk of blockages

- Performance is optimized per application.

- Wafer acquisition “watch dog”

- Application

- Back-side grinding/polishing

- Material diagnostics

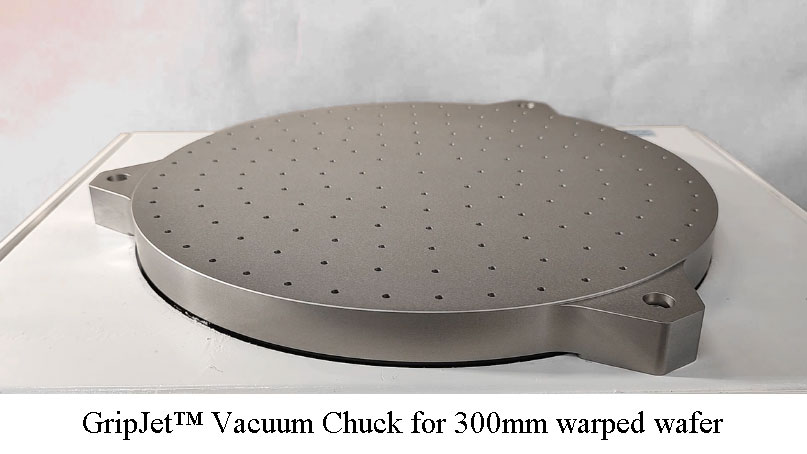

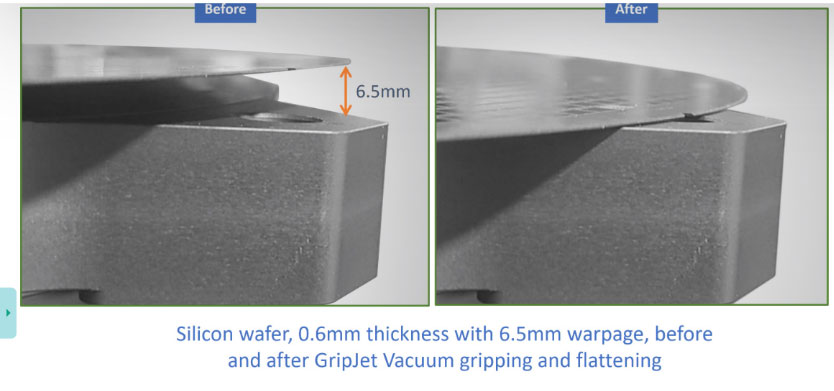

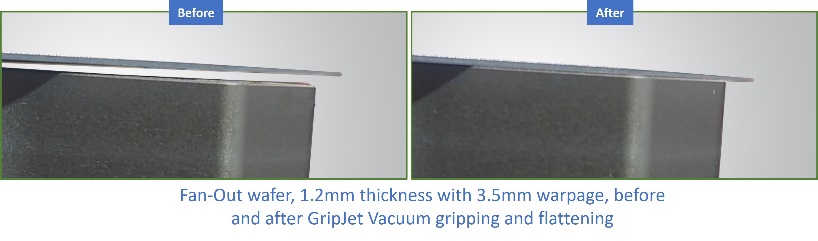

GripJet™ technology uses a special flow amplifier to increase the vacuum flow rate, allowing it to grip and flatten severely warped wafers without the use of direct contact with soft pads or any mechanical flattening mechanisms. It has successfully flattened 300mm diameter wafers with up to 8 mm of warpage. The GripJet™ chuck is easy to integrate into existing process tools, compatible with Class 100 environments, and ensures high reliability and cleanliness due to its unique design without moving parts or elastomers.

- Gripping & flattening highly warped wafers

- Avoid mechanical clamping and wafer damage

- Reduce down time

- Eliminate wafer back side contamination or pads marking

- High reliability, reduce maintenance cost & time

- Advanced wafer-level packaging (AWLP)

- wafer-level chip scale packaging (WLCSP)

- fan-out wafer-level packaging (FOWLP)

- AOI, Metrology, Defect Inspection, Lithography, and other Atmospheric processes.